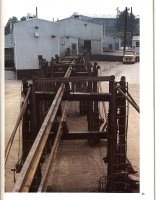

Welding Ribbons of Rail at Atlanta

Southern's Rail Welding and Track Assembly

at Inman Yard in Atlanta provides the ribbon

rail that helps ensure customers that their

freight will get a smooth, safe ride.

Spplying the rail needs of a progressive

railroad like Southern is a big job that may get

even bigger. In the future, the facility may be

called upon to supply the rail for Norfolk and

Western as well.

The Atlanta facility , a narrow strip of land just under a mile in length, helps make Southern's track smoother and longer lasting. That's a big job because Southern has 16,000 miles of track, including 10,000 route miles. Since the Atlanta facility opened in 1958, more than 2,373,800 welds have been made.

The train at left returns from the field with welded rail for reconditioning, while the other train with reconditioned rail is ready to roll.

Keeping Southern people busy on two shifts, the facility includes five plants: the rail welding plant, the rail renewal plant, the switch panel plant, the track panel plant, and the rail reclamation plant.

These plants are under the direction of Hubert L. Rose, assistant vice president, Maintenance of Way and Structures; Phil Ogden, chief engineer, System Gangs; and Jim Langley, manager of Rail Welding and Fabrication.

Let's look at what goes on at these plants. The rail welding plant and the rail rewelding plant are a complex of buildings, electromagnetic cranes, storage racks, roller conveyors, and welding machines. Both plants turn out 1,440 foot (quarter mile) strands of welded rail - sometimes called ribbon rail.

Why use welded rail? In jointed rail most of the wear occurs at the ends of rail section. Welded rail eliminates these joints and the maintenance problems associated with them.

Let's take the welding plant first. Although the plant welds both new and used rail sections into ribbon rail, most of the ribbon strands are mde of new rail. But new and old rail are not combined in the same strand. The strands are made from rail sections, usually 85 pounds to 136 pounds per yard, and varying in length from 25 to 39 feet.

"We've got some changes coming up" Mr. Rose said. Southern now looks forward to buying 78-foot rail sections. His will greatly reduce the number of welds needed to make a strand. This year's capital budget includes $3.9 million to expand our facility so we can handle these 78-foot sections.

Ribbons of rail move from the welding plant to storage racks.

During present operations, a huge electromagnetic crane unloads new 39-foot or

shorter rail sections from open gondola cars received from suppliers. The crane

places the rail on storage racks where it remains until it moves by roller by

conveyer to the welding area.

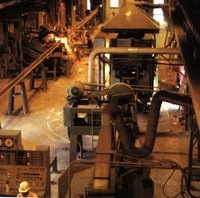

"The sections of rail are flash butt welded under enormous pressure," Mr. Rose

said "creating a bond as strong as the rail itself. Carrying 60,000 to 70,000 amperes

of electric current, the butting rail welds becomes white-hot."

In showers of sparks, 35 tons of pressure forges the heated rail ends together to

become literally on piece of metal. Then a machine shears off the bead of hot meal

that oozes up around the areas where the two ends meet. Next, a machine grinds

the wed to make it smoother, but the job still isn't complete.

An inspector further smoothes each weld with an electric grinder and uses

magnaflux testing equipment to make sure there a no cracks or imperfections, To

maintain quality control, an oscillograph monitors each weld.

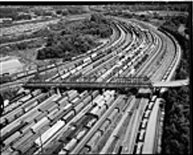

Strands of welded rail coming from the plant's two welding lines move first into

storage racks and finally onto one of Southern's six special rail trains, each consisting of 33 cars. The trains each carry 54 strands of ribbon rail (enough for 7.36 miles of track), plus all of the necessary tie plates, rail anchors, spikes and other fittings.

"Our rail-welding program began in 1958 when we could put down only

one strand of welded rail at a time," Mr. Rose said. "the following rear,

am improved dual rail-laying system reeled out tow strands of rail

simultaneously."

Southern now has more than 7,000 miles of welded rail. During

1981 the railway installed 473 miles of welded ribbon rail, including

236 miles of relay and released rail, which is reconditioned rail.

Southern also replaced more than 1.1 million cross ties and

resurfaced 2,229 miles of track.

Welded rail take off the main line is reconditioned at the rewelding

plant for use on secondary lines and on industrial sidings.

Like most track maintenance, the installation of welded rail carefully scheduled in advance. In colder months, Southern puts down rail in the southern part of its system. During the warmer months, the rail-laying forces shift their attention to the northern part of the system.

Whenever welded rail is installed the replace worn welded rail, the old rail - in quarter mile lengths is returned to Atlanta on the same rail train that delivered the new strands of rail. The used welded rail is taken to the rewelding plant - a story we'll get to later.

Whenever welded rail replace jointed rail, the old rail - still bolted together in quarter mile lengths - also is returned to Atlanta on the rail train.. At the facility's rail dismantling section, a series of machines removes the nuts and bolts that hold the rail joints together.

"Separated rail sections move by roller conveyors to the reclamation plant," Mr. Rose said. "Our people call this place the cropping plant. Here, four-way hydraulic press removes vertical and horizontal bends in the track sections. Then the worn rail ends with bolt holes are cropped off."

Much of this used rail goes to the welding plant to make quarter-mile strands of rail. There the used rail is welded together the same as new ail. Some reconditioned sections of rail are used at the rail switch plant. We'll get to these plants later.

Now, a few words about the facility's rail rewelding plant. When worn

welded rail is taken off the main line because it is no longer suitable

for high speeds and high tonnage, the rail is returned to the rewelding

plant. Thermite welds done in the field to link quarter-mile strands

together and any other rail joints are cut out of the quarter-mile strands.

After rail measurement and classification, similar grades of rail are

welded together for use on secondary main lines, sidings, and industry

track where the speeds and tonnage are lower.

An excess bead of metal is removed where two sections of rail were

flash butt welded under tremendous pressure.

The facility's rail switch plant assembles turn-out panels, and its rail panel

plant assembles sections of track. These operations are done at the rail

facility because the panels can be fabricated under controlled and highly

mechanized conditions in a fraction of the time required to do it in the field.

The turnout panels are used at location where trains have to be switched from one track to another. Track panels are used on construction projects such as yard track, sidings and industrial track. There is, however, a growing trend to use welded rail made at the rail rewelding plant for these purposes.

The track panel, a complete section of track, 30 to 39 feet long, is made of rail, ties, plates, spikes, and anchors. In addition to the materials required to make track panels, turnouts also require switch points, frogs, and switch plates.

Specially designed cars move the switch and track panels out into the field. Each car has its own power for unloading the panels at the construction site. A car loaded with track panels carries enough track for about 300 feet of rail.

New welded rail, and carefully assembled switch and track panels

give track a longer life and shipments a better ride. That’s rail

progress for the road ahead.

The above pictures and text were taken from the June 1982 issue of

Norfolk Southern World Magazine.

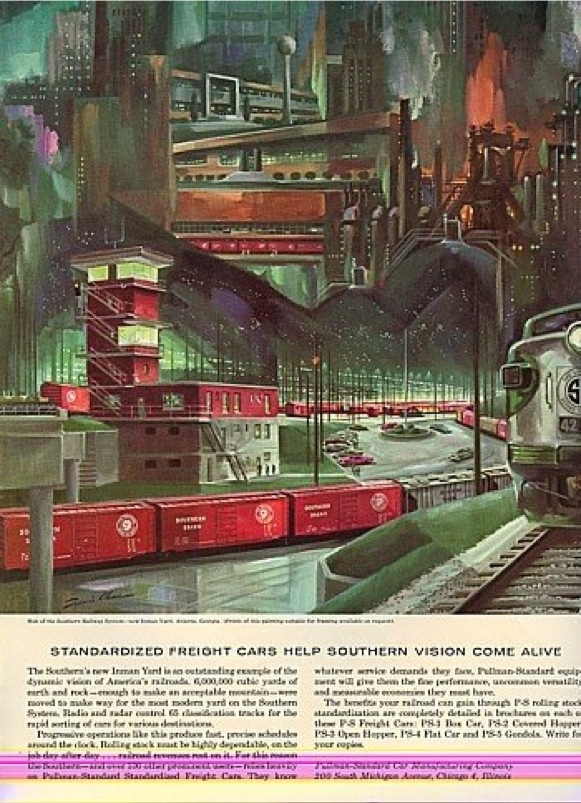

1958 Pullman Ad

Southern Railway

Inman Yard Atlanta Ga.